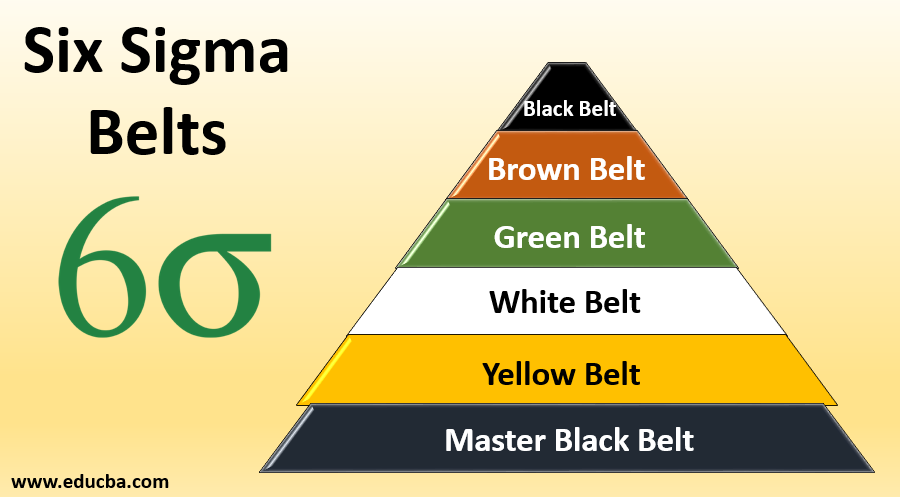

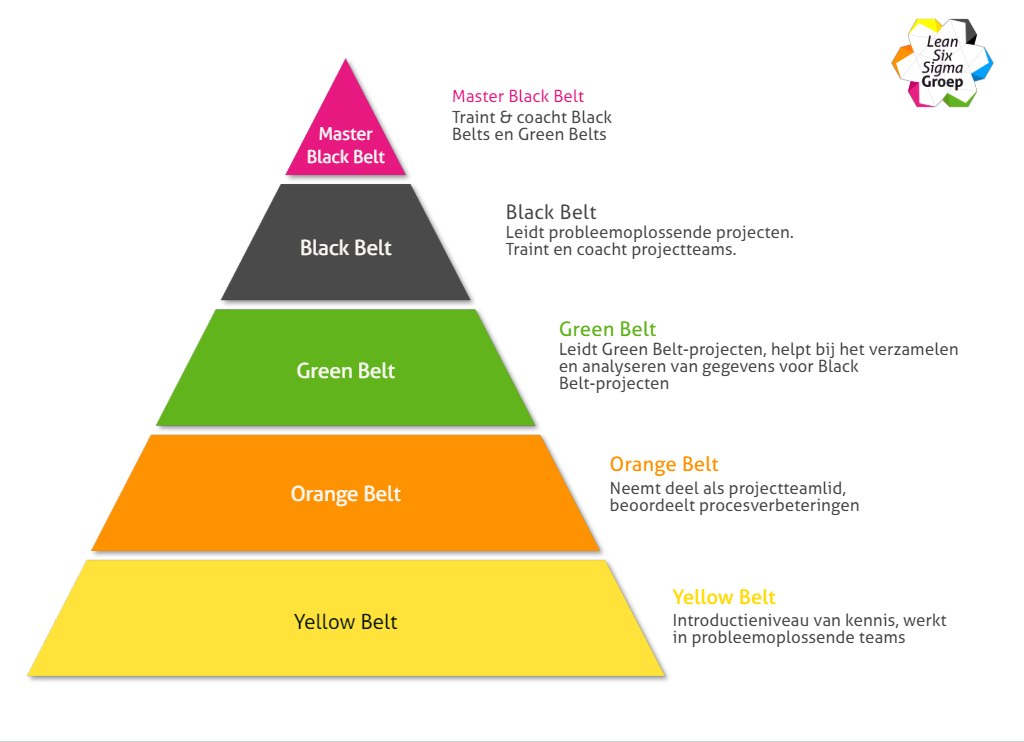

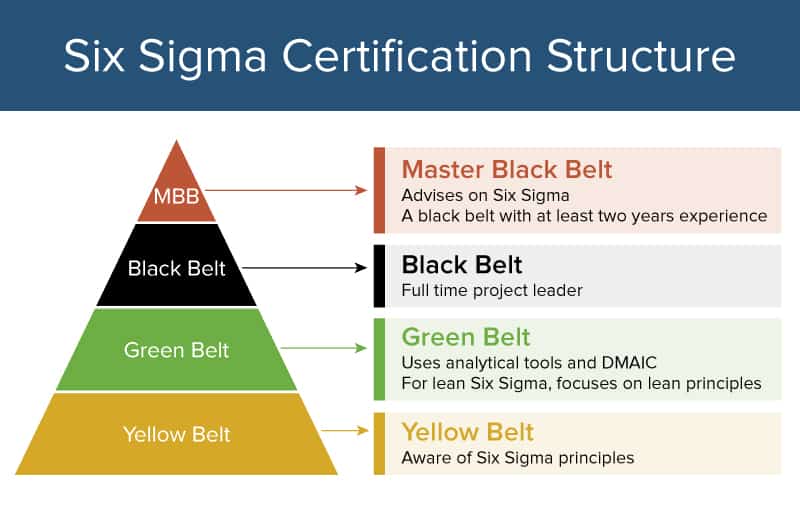

The average salary for certified Green Belt specialists starts at $75K. They say Green Belts are the real workhorses of a business. They usually get the support of Black Belts to whom they are assigned for coaching and mentoring. They lead their team members through the project framework and toolset, decrease defects in the process, and try to evaluate solutions. They strive to improve processes they are a part of on a part-time basis. The role of Green Belt specialists is to implement Lean Six Sigma projects within their department and as part of their job. The Six Sigma Green Belt is aimed to teach you to solve many process challenges through approximately 10 days of training. It allows them to understand the source tenets, learn relevant statistical concepts, apply graphical analysis, and process management, as well as gain a basic understanding of the DMAIC method. The Yellow Belt Certification enables professionals to have basic knowledge of the Six Sigma principles, terminologies, processes, and tools. They help bring projects into completion, solving possible problems. As team members, they attend meetings, initiate functional inputs, collect project data, and help in testing issues. Yellow belt specialists know 6 Sigma fundamentals but are not fully trained to lead projects. The Yellow Belt indicates the entry-level rank in the Lean Six Sigma hierarchy. The White Belt assists teams in problem-solving and helps to instill the Six Sigma culture into the workplace. This role provides professionals with a basic knowledge of Six Sigma and its vocabulary. White Belts can be achieved by front-line workers and corporate executives. The main goal of the White Belt Certification is to understand the fundamental concepts of Six Sigma. Earning this certification level looks ideal for professionals that want to begin their Six Sigma journey and learn more about the methodology. The White Belt is a field of interest for Six Sigma beginners. Now let’s explore all the Lean Six Sigma Belts in more detail. People who have this belt have extensive experience and can lead their fields. This belt is the top of the Lean Six Sigma achievement structure. Having the Black Belt, you may directly influence organizational changes. This certification indicates your expert level in Six Sigma philosophy. The belt focuses on advanced analysis and resolution of problems related to quality improvement projects. This certification proves that you have learned the Six Sigma specifics before and know how the disciplines are applied to the workplace. It demonstrates an introductory level of knowledge to Six Sigma. You can achieve particular certification levels, getting the following Six Sigma Belts: If you strive to get Six Sigma Certification, you must follow a hierarchical process. The method of Six Sigma provides the use of a colored belt tier system for its certification. In order to understand how employees’ skills can be applied in a Six Sigma project, it is worth understanding what each belt means. This reference to colors is a simple and effective way to quickly understand the skill set and experience level of specialists. Each role varies from Yellow Belt to the Master Black belt. In Japan, they are distinguished by specific colored belts. This technique has specific levels of practitioners that are evaluated according to their skills & expertise. The genesis for the Six Sigma Belts notations comes from Japanese martial art, known as Karate. White, yellow, green, black belts… what does it mean? These are common notations among the professionals who get different levels in the Six Sigma certification.

Let’s figure them out right here in our post!

How many belts are there in Six Sigma? What do the Six Sigma belts mean? What is the first belt in this system? Well, it seems that there are so many questions. You have probably heard about Six Sigma professionals who are entitled to specific color belts.

The key goal of Six Sigma is to streamline business processes by decreasing defects, variations, and wastes in a product or service, at the same time improving employee morale and quality of products. Six Sigma provides qualitative tools to improve the capability of business processes. Many organizations from various industries have accomplished this through the Six Sigma method that was designed to increase process efficiency through a disciplined, data-driven approach.

Any company continually strives to maximize resources to its extent and streamline its processes to improve efficiency and performance.

0 kommentar(er)

0 kommentar(er)